Rectangular Ducting

Rectangular ducting refers to a type of ventilation or air conditioning system that utilizes rectangular-shaped ducts to transport air from one location to another. It is commonly used in residential, commercial, and industrial buildings to distribute conditioned air or remove stale air and pollutants.

- Rectangular ducting is characterized by its rectangular cross-sectional shape. It typically has four straight sides with sharp corners, forming a rectangular enclosure for the passage of air or other substances.

- Rectangular ducting is usually made from sheet metal such as galvanized steel or aluminum. The chosen material provides strength, durability, and resistance to corrosion.

- : Rectangular ducting comes in various sizes and dimensions to accommodate different airflow requirements and space limitations.

- Rectangular ducting can be insulated to minimize heat transfer and prevent condensation. Insulation helps maintain the temperature of the air inside the duct and reduces energy losses.

The design of rectangular ducting consists of straight sections that are interconnected by joints or fittings. These fittings can include elbows, transitions, offsets, and dampers to redirect airflow or control the volume of air. The ducts may also have insulation on the exterior to prevent heat transfer and minimize energy loss.

Spiral Ducting

Spiral ducting, also known as spiral or round duct, is a type of ductwork commonly used in HVAC (Heating, Ventilation, and Air Conditioning) systems for commercial and industrial applications. It is characterized by its spiral shape, which offers several advantages over traditional rectangular ductwork.

- Spiral ducting is constructed in a spiral shape, with a continuous helical seam running along its length. This design provides structural integrity and ensures airtightness.

- Spiral ducting is typically made from galvanized steel, stainless steel, or aluminum. The choice of material depends on factors such as the application, desired durability, and corrosion resistance.

- Spiral ducting has a smooth interior surface, which reduces air friction and pressure drop, resulting in improved airflow efficiency.

- Spiral ducting is relatively easy to install compared to other types of ductwork. The spiral design eliminates the need for many joints and connections, reducing installation time and labor costs.

- Spiral ducting is known for its durability and longevity. The materials used are resistant to corrosion, moisture, and other environmental factors, ensuring a long service life.

Spiral ducting offers numerous advantages over traditional rectangular ductwork, including improved airflow efficiency, energy savings, durability, leak resistance, noise reduction, space efficiency, easy installation, and aesthetic appeal.

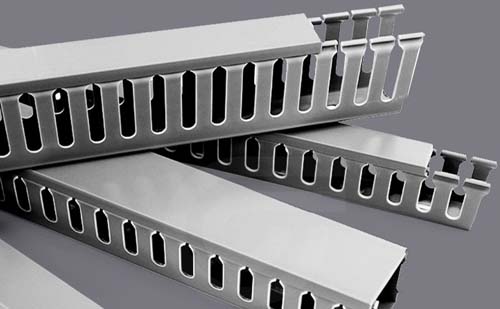

Electrical Ducting

Electrical ducting refers to a system of conduits or channels used to enclose and protect electrical cables and wiring. It provides a safe and organized means of routing and concealing electrical wiring in residential, commercial, and industrial buildings.

- Electrical ducting can be made from various materials, including PVC (Polyvinyl Chloride), steel, aluminum, or fiberglass.

- Electrical ducting comes in different sizes and shapes to accommodate various types and quantities of cables. Common shapes include rectangular, square, and circular, with standard sizes defined by industry standards.

- Electrical ducting is designed to hold and manage multiple cables of different sizes. It allows for easy installation, maintenance, and expansion of electrical systems.

- One of the primary purposes of electrical ducting is to provide protection to electrical cables. It shields them from physical damage, moisture, dust.

- Electrical ducting is designed to be compatible with other components of the electrical system, such as connectors, fittings, and junction boxes. This ensures seamless integration and ease of installation.

Electrical ducting provides a crucial infrastructure for safely managing and organizing electrical wiring within buildings. It ensures the efficient and reliable distribution of electricity while minimizing risks associated with electrical installations.